Smythson: A Legacy of Craft

Smythson is proud to appear in this year’s Walpole Book of British Luxury, a prestigious annual publication celebrating the very best of British craftsmanship. Walpole brings together 250 of Britain’s most esteemed brands and works to promote, protect and develop the British luxury sector, championing the creativity, heritage and excellence that make it world-renowned. In the Meet the Makers section, Mark Hooper’s essay explores the artistry and techniques that have defined Smythson for over 135 years, shining a light on the people and processes behind our products.

When Frank Smythson opened his first store on London’s New Bond Street in 1887, he described himself as a purveyor of “stationery and fancy articles of a high-class character”. Almost 140 years later, Smythson’s iconic diaries, together with a curated range of notebooks, writing paper, leather bags and accessories, remain the last word in luxury. Proud holders of a Royal Warrant since 1964, the brand still uses the same tried and tested techniques in its Hertfordshire workshop.

“It's all the same skills, same equipment, same hand-fed, hand-finished products,” says Production and Site Manager Mark Bateman. “It’s what keeps the name going on and keeps the customer coming back.”

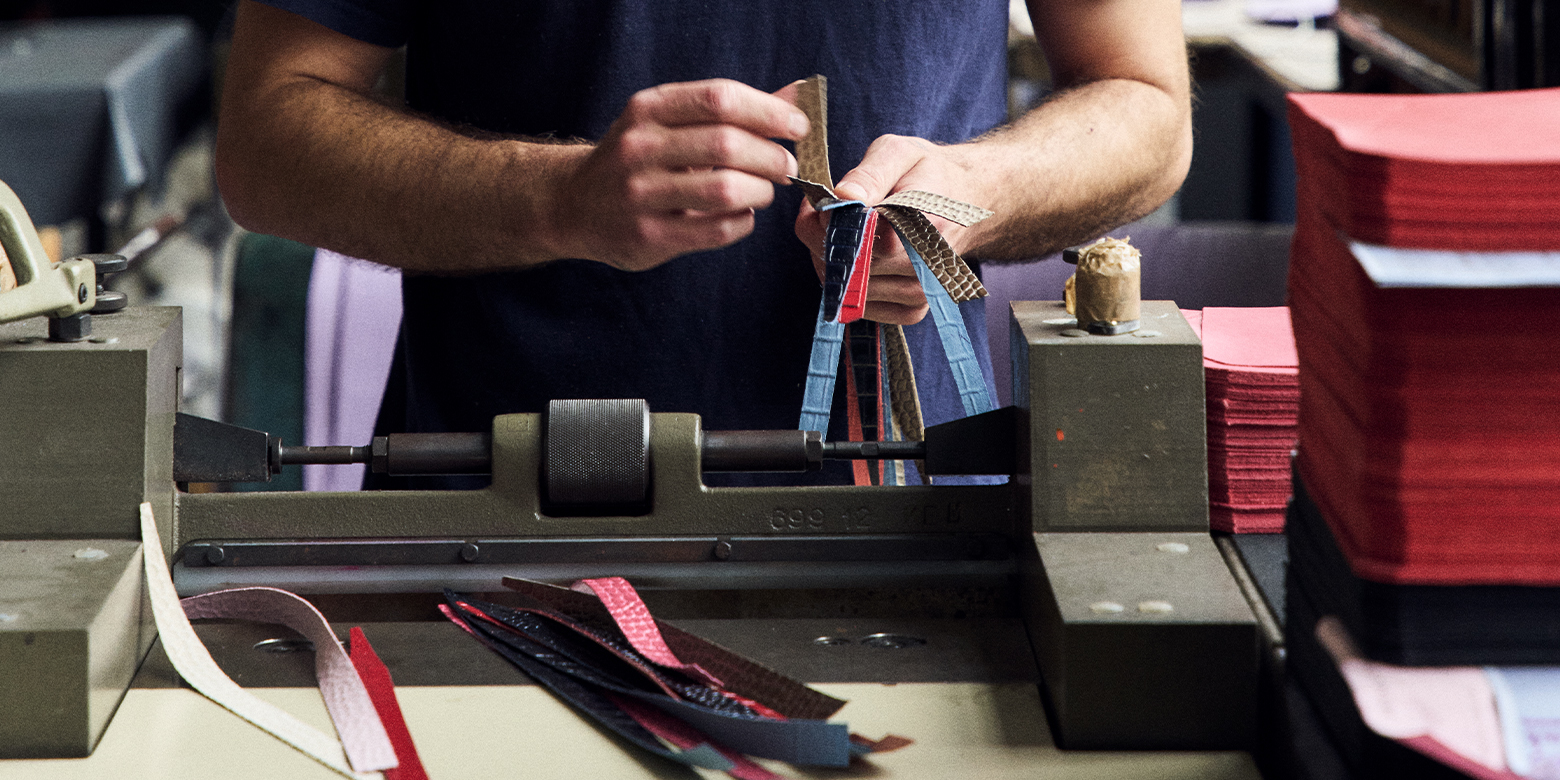

“We're the best at what we do, really,” adds Production Coordinator Ross Pearce. “I love seeing all the processes come together, from a hide of leather and a sheet of paper. And by the end of that process, whether it’s cut, it's gilt, it's trimmed… it's gone through many hands. And then when someone picks it up, and says, ‘Wow, look at this, it’s really well made,’ that’s a nice feeling – the fact that something you do, other people take pride in.”

Asked what they themselves take pride in, the team, almost to a person, cite their ability to work with the gossamer-thin, 50-gram Featherweight watermarked paper – something that many auto-fed commercial presses would struggle to handle without a considerable degree of wastage from creasing (“Someone said it's like folding mist!” says Bateman).

Running the traditional press is a highly skilled – and dying – art (given the dominance of digital presses). The thinness of the paper requires the machines to run slower than standard, but economics dictate that speed and efficiency are never compromised too much. It’s a fine balancing act that requires meticulous planning, teamwork and trust that each individual department does their job to perfection. The printing, trimming, glueing and gilding all have to be spot-on before moving on to the next stage.

Watching the dedicated teams in action, it’s clear that the decades of experience on display at Smythson extend to numerous little tricks that have been passed down over the years. For instance, the glue must be watered down on hotter days, when it tends to thicken – a particular hazard for bench work (where the paper book and leather casing are assembled) and book binding.

With so much that can potentially go wrong, Bateman describes how coordinating the many processes can be “like spinning plates” – particularly as they offer an array of variable bespoke options. But by far his biggest challenge is to find people with the right aptitude to fill roles when skilled staff leave or retire. In fact, he finds a degree of lateral thinking often pays dividends when it comes to employment. “We've taken on a few former chefs, because they're good with their hands and they're hard workers.”

Although many of the staff refer to the relaxed atmosphere and supportive, family feeling throughout the workshop, there is no question that the standards they achieve are paramount. “It’s about being challenged to produce perfection, because that's what's expected,” says Pearce. “That’s what the minimum requirement is. It doesn't matter how long the process takes or what you have to do, it has to be perfect. And anything less than that won’t do… I've stolen this motto from my football team: Nil Satis Nisi Optimum. Which means nothing but the best is good enough.”

As well as the ongoing strive for perfection, as a company, Smythson is always keen to embrace new ideas, constantly evolving their systems to ensure they can meet the demands of their customers and offer as bespoke a service as possible, whilst always keeping the design timeless. After all, it’s served the brand well for nearly 140 years, combining craftsmanship with cutting-edge expertise – and that is the reason they have built a hugely loyal customer base who return for the products, year-on-year.

When the diaries are finally assembled, with their trademark gilt-edged pages sat within their leather covers, the team can finally allow themselves a moment of quiet satisfaction. High-class character guaranteed, as Frank Smythson would have said.

Words: Mark Hooper

Photography: Sam Walton